- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

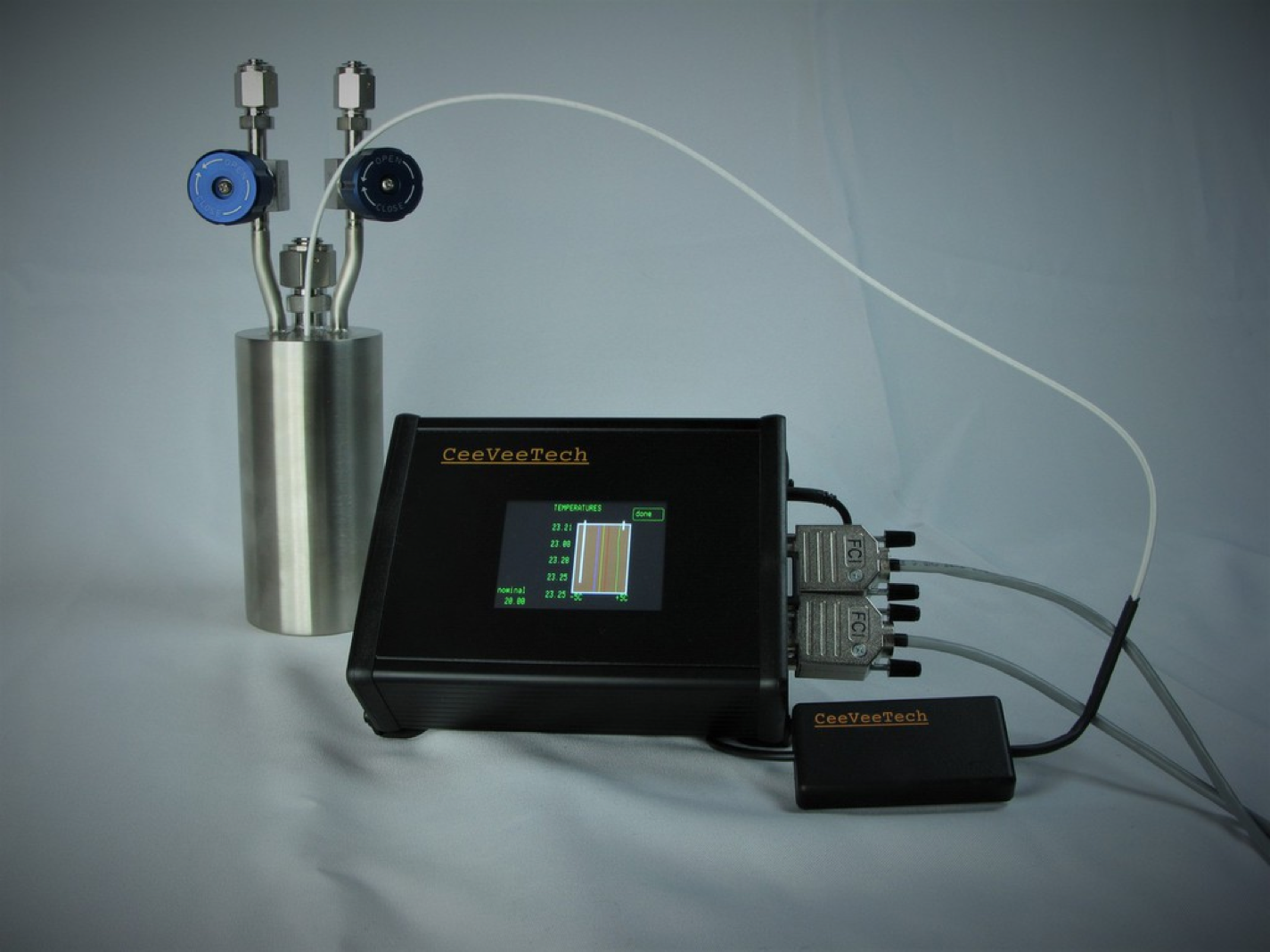

Innovent was asked to work from customer concepts to design a chamber for precise temperature control of precursor compounds. The technical challenge was to design a chamber geometry was the most efficient for the application. Material thermal properties were critical to insure compatibility with the design. An additional design constraint was that the finished unit had be easyily adaptable to older equipment.

CeeVeeTech partnered with Innovent Technologies, LLC who has a long history of collaborating with customers on how best to implement groundbreaking improvements to technology and processes, (see ALD and OOR Pulley’s Case Studies).

Once a business plan, engineering proposal and timeline were agreed upon, the correct resources were assigned, and the project was kicked-off.

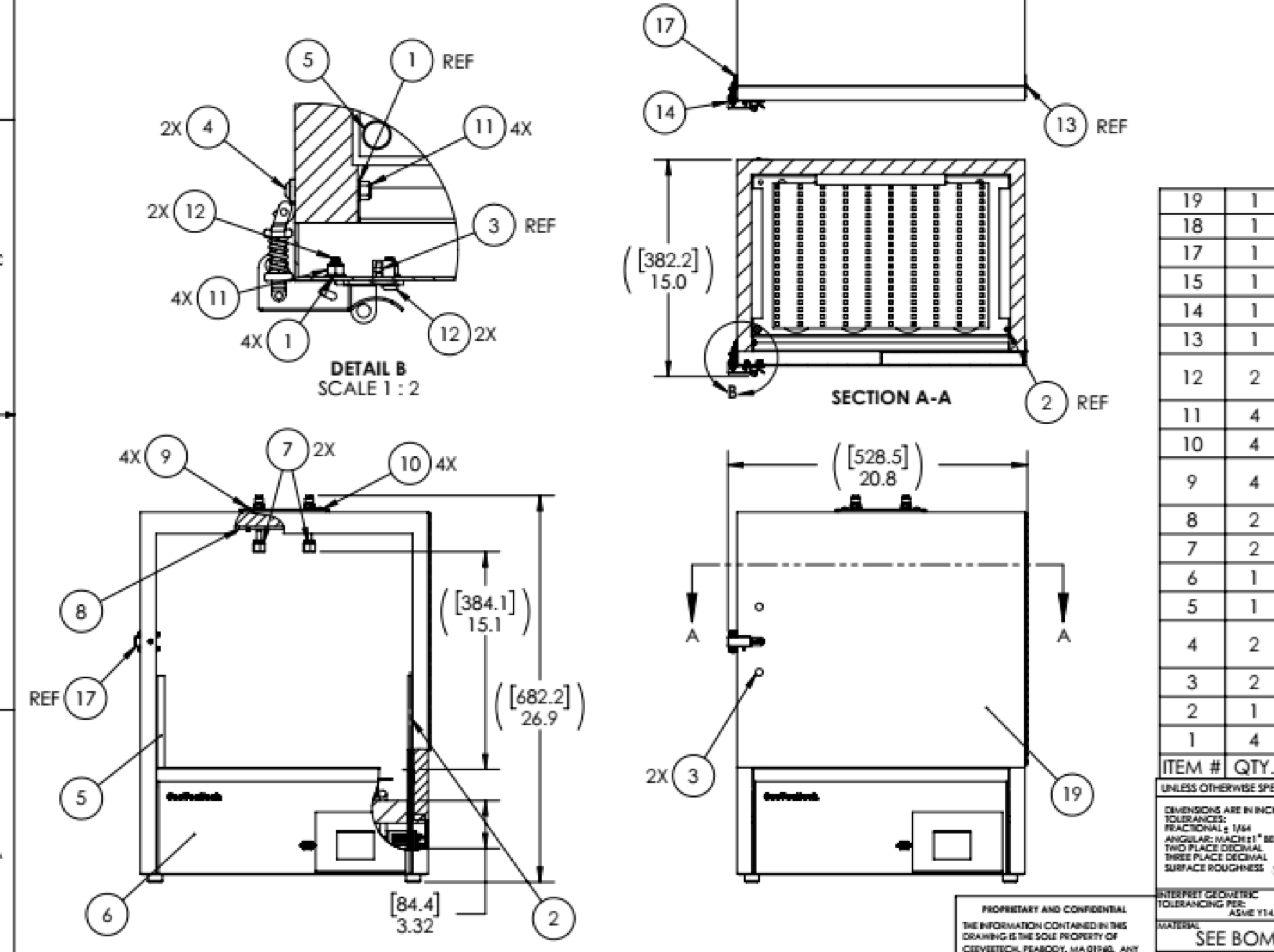

The approach to this project was no different than any other. The Design Engineer was tasked with transforming the customers concepts and ideas into a visual format i.e., Solidworks modeling. The goals in this critical Concept and Design phase were to achieve design and cost specification within the time allotted. We recognized that this phase is one of creation and as such the likelihood of changes is high so time must be allotted for consideration of design alternatives based on everything from material selection, component costs, efficiency of manufacturing to commonality of hardware and finish specifications.

A BOM and Detail drawings were created, design reviews were conducted, and the procurement team was leveraged to handle the quoting process. Some components were considered for internal fabrication while others went out to our extensive supply chain for pricing.

Once a PO was issued, the rest of the organization was called on to perform their respective job functions of procuring material, establishing a work cell, creating fixturing, performing assembly, test and product qualification.

This adaptive planning and execution process is tailored to meet the client’s needs and exhibit the flexibility required from a manufacturing partner. With a small staff of engineers, we welcome any electromechanical manufacturing challenges that you may have which is a testament to this and many other success stories.

A collaborative relationship was established with the customer to work through several concepts. Once an agreement was made, we quickly generated a final design package that was approved with minimum issues. The initial build of four units went smoothly, the design met the specifications under testing, and proved to be reliable.

At a postmortem design review revealed only minor issues relating to the overall design. The units were shipped to customer sites and feedback has been positive.

Innovent provided the resources and the expertise to transform CeeVeeTech’s product ideas into finished products. With the help of Innovent we drafted the design with an eye on manufacturability and maintenance. Once the design and the plans were finished Innovent handled the purchasing and fabrication of parts and the assembly of the product. We are very happy about every aspect of our partnership with Innovent.