- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

Welds must be strong, uniform, and free of defects to ensure the safety and reliability of the final product. That’s where orbital welding comes in. This specialized welding technique is used to produce high-quality, consistent welds in a variety of industries, including aerospace, pharmaceuticals, semiconductor manufacturing, and power generation.

Orbital welding involves the use of a welding head that rotates around the workpiece while simultaneously feeding a filler material into the weld joint. The process is fully automated, which eliminates the potential for human error. The welding head is designed to maintain a consistent arc length and speed throughout the weld, which helps to ensure uniformity and quality.

Additionally, the process can be performed in difficult-to-reach locations, making it ideal for use in confined spaces or on components that are too large or complex for manual welding.

Another benefit of orbital welding is its ability to meet stringent quality standards. The process produces welds that are uniform, strong, and free of defects, which is essential in industries where safety and reliability are paramount.

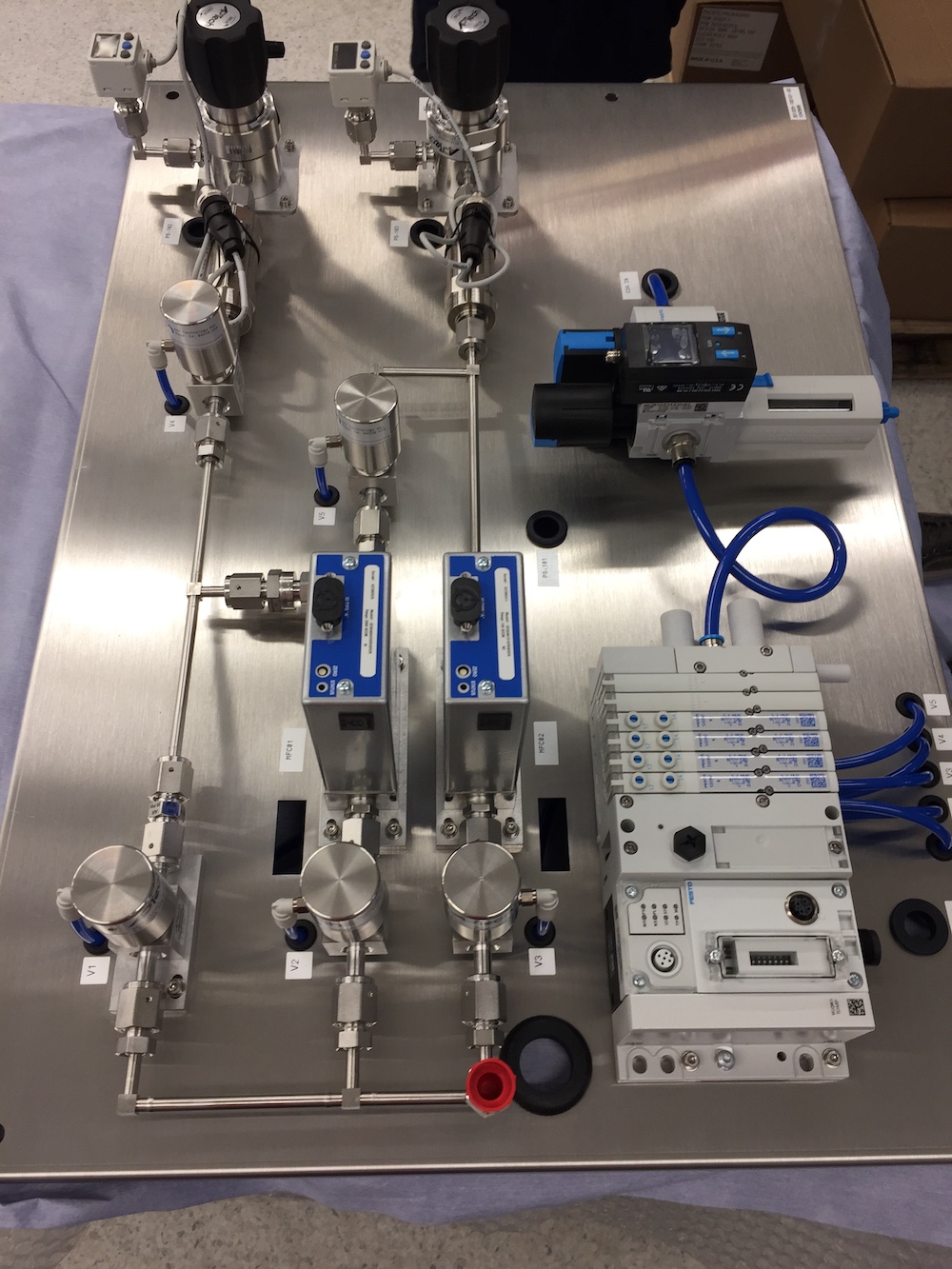

At our company, we specialize in providing contract manufacturing services to a variety of industries. We understand the importance of quality and efficiency, which is why we use the latest technologies and techniques, including orbital welding, to produce the highest quality products for our customers.

If you’re looking for a reliable contract manufacturer that can deliver high-quality products, contact us today to learn more about our services and how we can help you achieve your manufacturing goals.

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now