- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

Our EE solutions are specially tailored to handle silicon and glass substrates, which are critical components in the semiconductor manufacturing process. We offer aluminum vacuum and active edge grip EE with Teflon coating for increased corrosion resistance, ensuring that our products are durable and reliable in harsh environments.

We also provide stainless steel passive EE with no coating for operation in vacuum, which is ideal for applications that require a clean, contamination-free environment. In addition, we offer EE with O-ring platforms designed to fit suction cups for bowed wafer applications, providing a customized solution to meet specific requirements.

Aluminum vacuum EE with Teflon coating for increased corrosion resistance. Pads are made to be coplanar within 0.0005″ (.013mm), to guarantee a wafer “pick” every time.

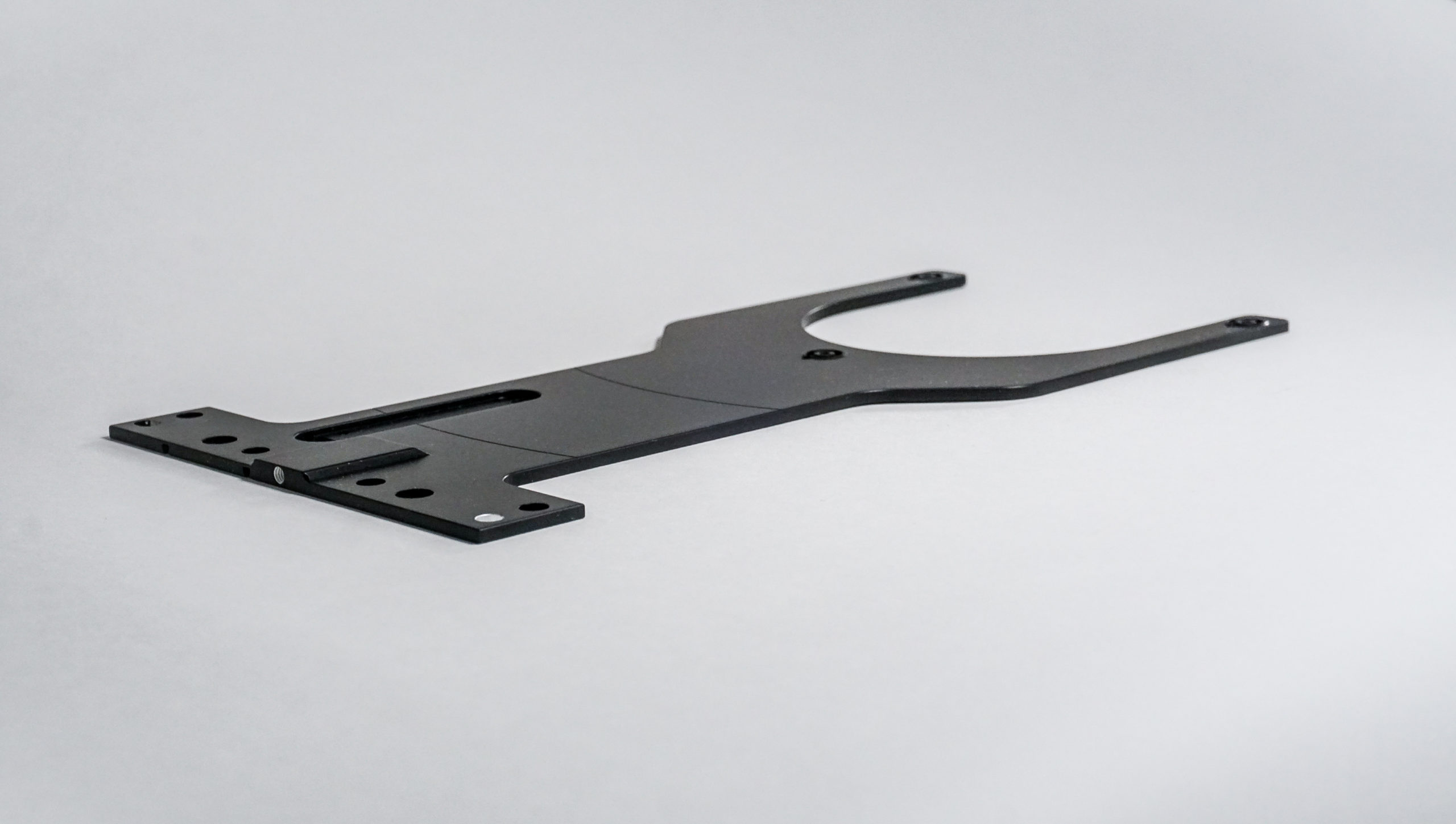

SST passive EE with DLC coating to create a uniform matte finish. This matte finish helps maximize the refraction of fiber-optic signals to aid in wafer presence applications. EE is straightened to within 0.002″ (0.05mm) flatness to prevent wafer/FOUP collisions.

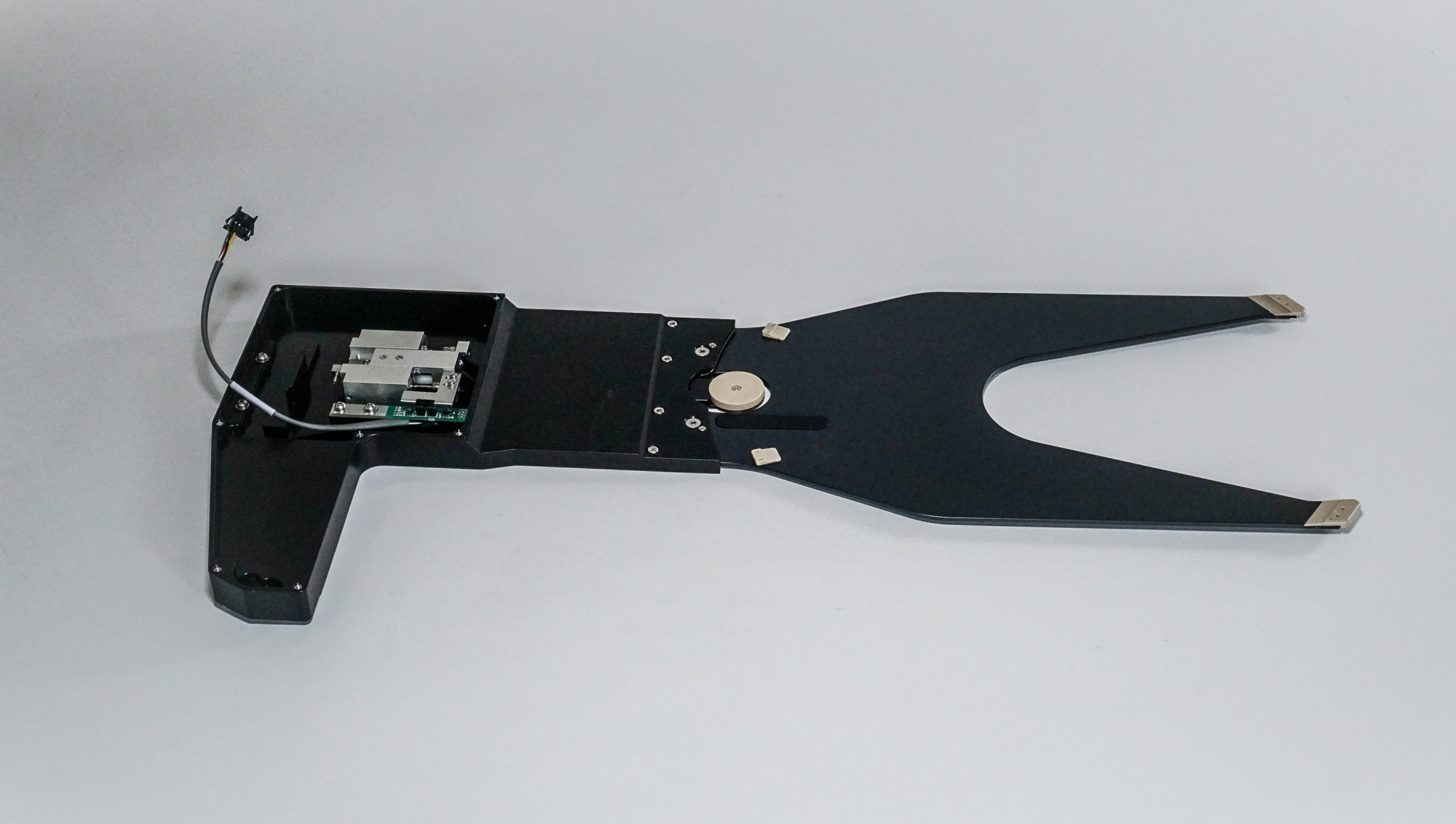

SST passive EE with no coating for operation in vacuum. Dovetail channels are run up the tines as well as through the wrist for dual wafer presence/wafer mapping applications. Dovetails allow for easy encapsulation of fiber optic cables.

Aluminum vacuum EE with anodize finish. Built-in wrist minimizes the number of components and tolerance stack-ups. Built-in pads are lapped to a mirror finish to provide vacuum sealing ability and minimize wafer particle contaminants.

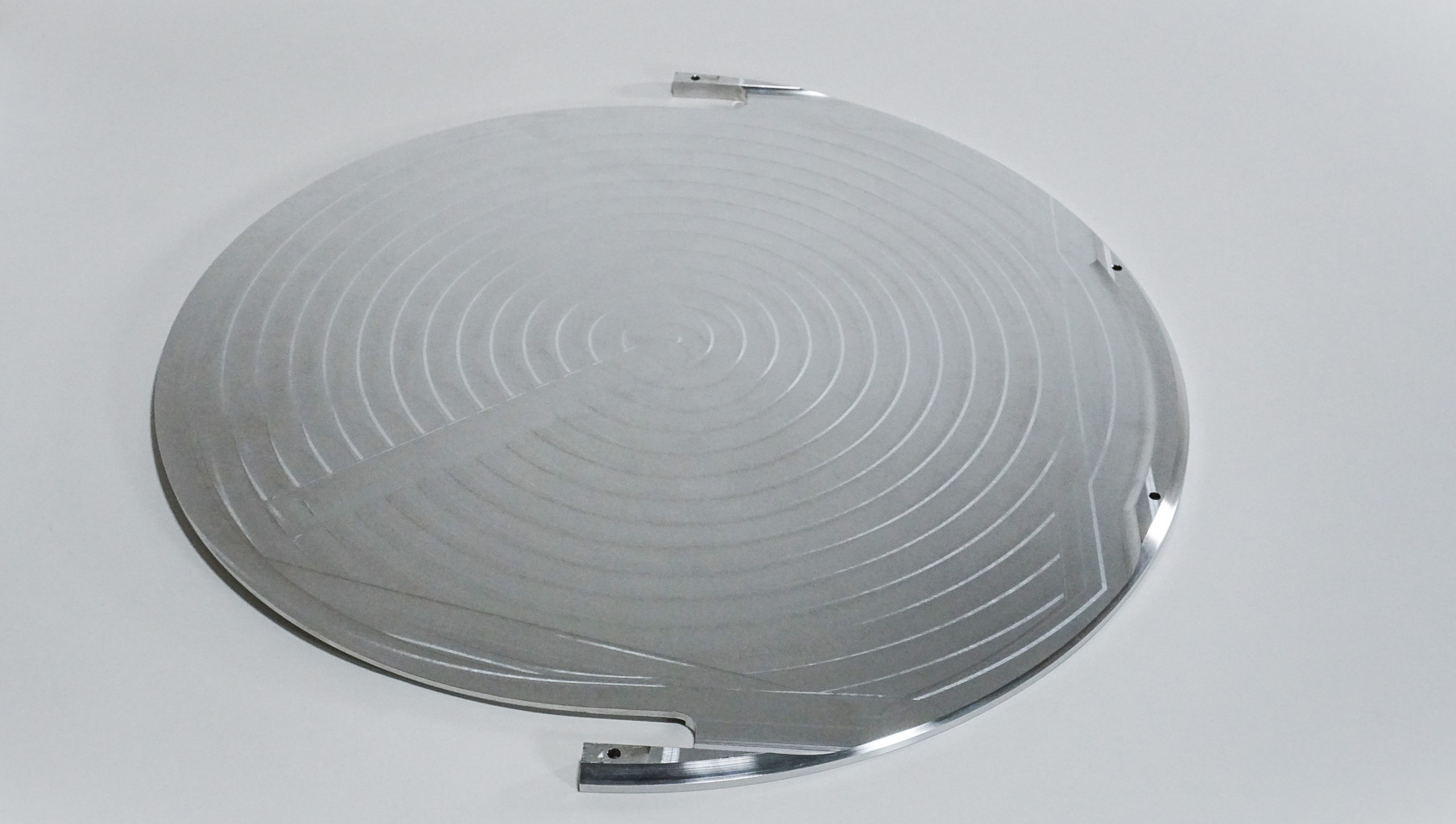

Aluminum wafer tray with no coating for operation in vacuum. Designed for 450MM wafers, this blade is flattened to within 0.005′ (0.13mm), to allow for consistent wafer “picks”.

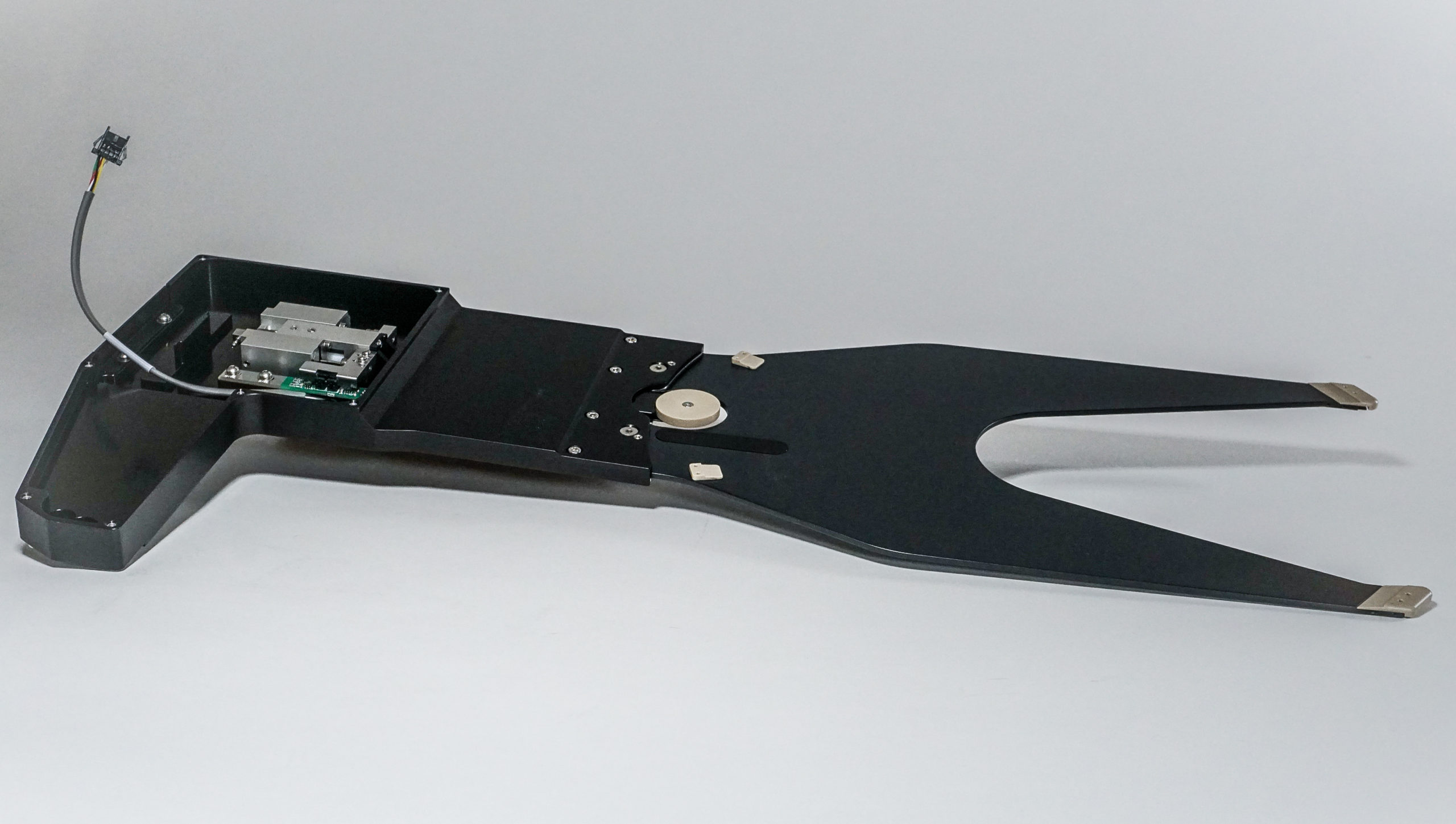

Aluminum active edge grip EE with Teflon coating for increased corrosion resistance. Wrist and Support components are assembled and cycled in-house for a turn-key solution into EFEM.

Aluminum vacuum EE with anodize finish. O-ring platforms designed to fit suction cups for bowed wafer applications up to 0.080″ (2mm) of both convex and concave bowing.

With our technical expertise and unmatched capabilities, we are the only supplier you need to consider for all things End Effector. Contact us today to learn more about how we can help solve your design, fabrication, and manufacturing challenges.

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now