- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

Once a project is in progress and the price is set, these are the two things the customer deals with on a daily basis. In a lean supply chain, which all modern OEM manufacturing companies are working with, on-time delivery (OTD) is vital to their success. Minor hiccups in our delivery of OEM products can halt their production lines causing thousands of dollars of losses per day. Quality issues show up as intermittent interruptions and can be a real headache to customers. If found in the later stages of the manufacturing process, the delays and costs can be very high. OTD and quality are directly proportional to customer satisfaction.

A key part of our improvement process is quality and engineering teamwork to determine root causes and actions to be taken. These can be process, workmanship, or supply chain issues that need to be fixed. We have a customer service mindset and make quality and OTD an extremely high priority in our day-to-day operations. Our customers have come to expect their OEM parts to be out the door on time and exactly as specified. It puts a lot of pressure on us, and we consistently deliver.

At Innovent, we have a team of dedicated professionals who demand on-time delivery as key to our success. We understand that our customers depend on us for OTD and quality of high performing OEM parts. Everything we do is with OTD and quality top of mind so our customers can depend on us.

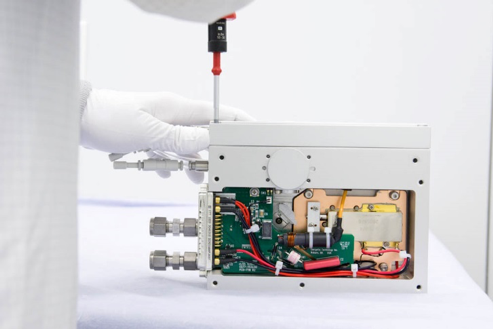

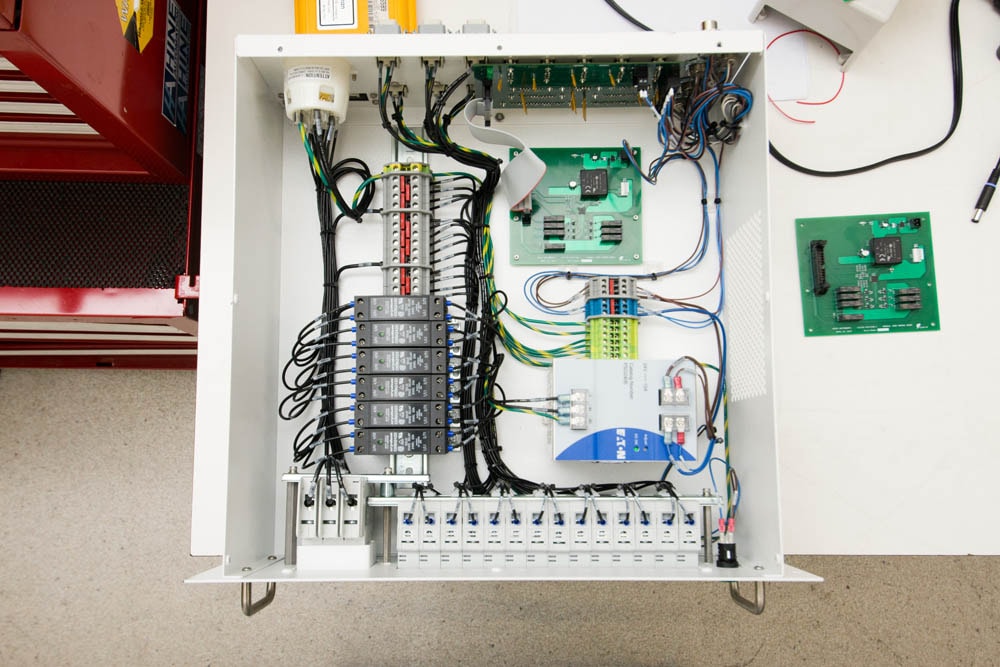

Innovents System Integration and testing includes:

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now