- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

Cleanroom Manufacturing

Precision Machining & Welding

Assembly & Integration

System Testing Qualification

Engineering

Fast-turn Prototype

OEM level Engineering while collaborating with customers on design reviews before release to production.

Unparalleled knowledge of system assemblies and other process-critical items.

Complete manufacturing infrastructure in place with qualified suppliers and subcontractors.

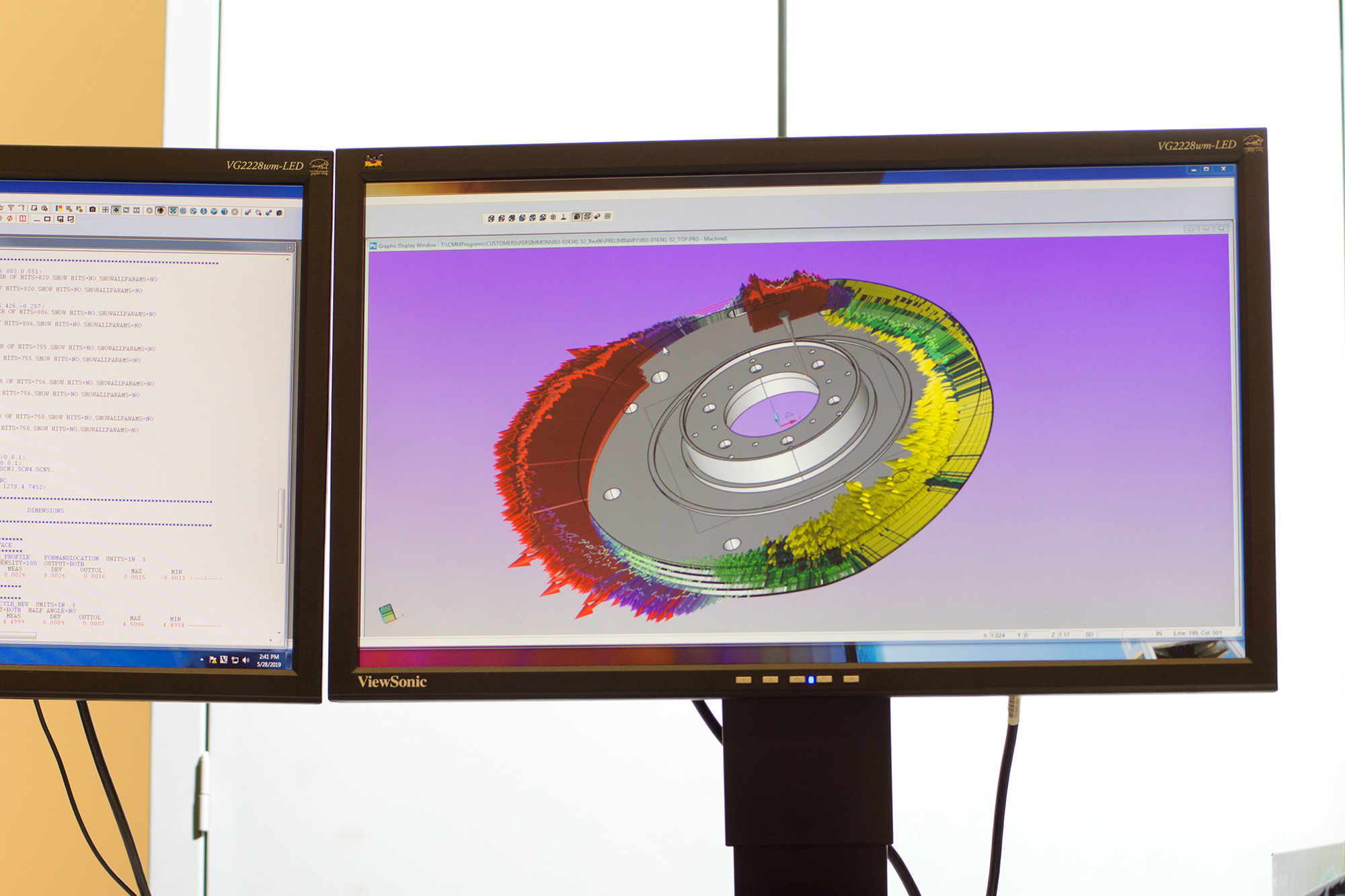

Experience working with prototype through volume production High Mix / Low Volume CNC Machining

Horizontal CNC Pallet Milling Centers (4)

Vertical CNC Milling Centers (5)

Manual Equipment

We precision machine the most complex and innovative substrate handling components from a variety of metals to precise tolerances for the semiconductor industry.

Vertical integration is the key to our success. Raw material is transformed into highly refined components though our CNC, welding, and polishing processes. Some of those components move on to our clean work cells for assembly, test and qualification of larger tools and systems.

Our adaptive planning process is tailored to meet our customers low to medium-volume/high-mix requirements and exhibit the flexibility required from a manufacturing partner.

We are able to provide you with clean room manufacturing for your most critical and contamination sensitive products.

Assemblies and products are tested, cleaned and packaged to SEMI standards so that they can be moved directly into the cleanroom at either the OEM or FAB location. We have immediate capacity to manufacture your products in this Clean and Controlled Environment.

Innovent’s Vertical Integration is a backbone within the organization.

It exists primarily to provide quick turn prototyping for your new ideas or problem solutions and long-term, process controlled production of both. We investigate all options to insure sound make/buy decisions for all machining needs.

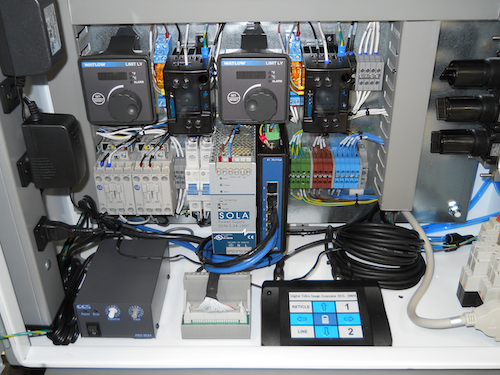

Innovent can produce complex assemblies ranging from box-builds and electro-mechanical assemblies to complete system integration.

We either utilize your product manufacturing documentation, or we create it internally.

We know that the best way to serve our customers is by understanding their business and the products they offer. We assign engineering resources at the onset of the relationship. This single point of contact backed by the support of the entire organization provides an unparalleled level of service.

We are experts in cost reduction through manufacturing process refinement and product redesign. Innovent’s product design team can create customized solutions for quick-turn engineering trials or high volume manufacture of components, sub-assemblies and complete products.

Innovent has the internal resources to develop the alpha versions of your designs.

Worked from customer concepts to design a chamber for precise temperature control of precursor compounds.

Innovent’s electromechanical box build capability is focused on solving our customer’s excess demand or quality/delivery issues by providing box build contract manufacturing for complex assemblies.

We have delivered box build projects for medical, semiconductor, life science, nanotechnology equipment and a wide range of other industries. We offer IPC certified technicians with years of experience and an extensive array of equipment and instruments.

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now