- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

The semiconductor capital and laboratory equipment manufacturing companies, like Innovent, specialize in producing equipment for the semiconductor industry, including semiconductor manufacturing equipment, wafer processing equipment, and other tools used in chip fabrication.

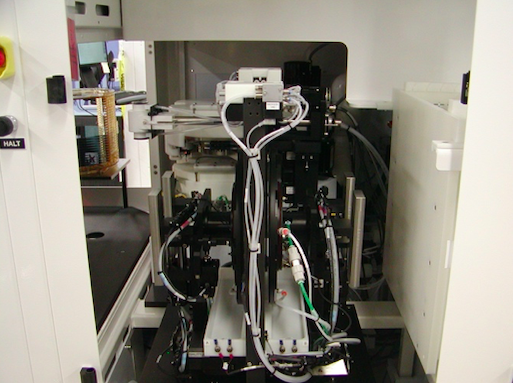

The largest percentage of semiconductor capital equipment investment goes toward FEOL (front-end-of-line) wafer manufacturing, involving four main component categories: Deposition, lithography, etch, and clean, which also includes process control. The smaller part of the investments goes to BEOL (back-end-of-line), referring to wafer testing and IC packaging. semiconductor machine manufacturers have been actively engaged in projects across various stages of chip manufacturing, contributing a diverse range of wafer transport and processing components, such as end effectors and chucks, to fully assembled robotic transport systems.

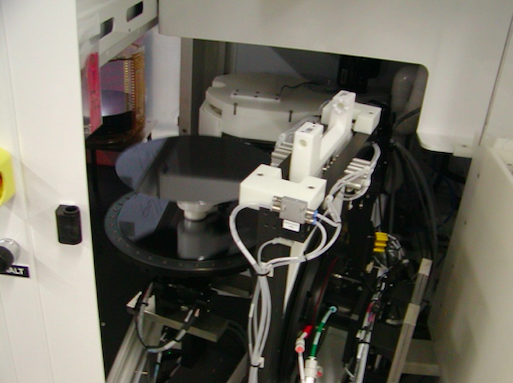

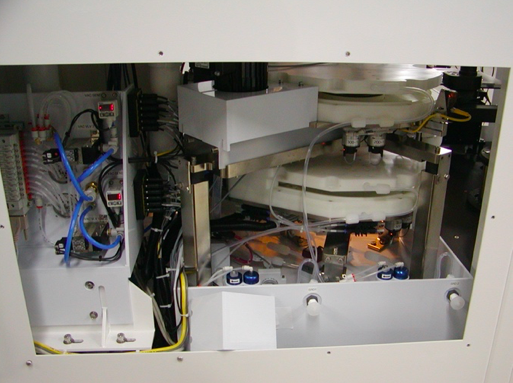

Atmosphere and vacuum process applications are also within our specialty, encompassing wafer marking, atomic-level, and chemical vapor deposition tools. In addition, we design and test wafer pick-and-placement Robotic Assemblies for electro-chemical capital equipment and Rinse Cells for Wafer Plating tools.

We pride ourselves in having close to two decades of experience to meet this continually evolving industry. Our Engineers and Technicians possess a specialized set of skills, technical ability, knowledge and expertise to produce semiconductor capital and laboratory manufacturing tools of the highest caliber. We are relied on to efficiently and consistently execute the assembly, test and qualification process for these highly complex tools.

Vertical integration is one of the significant values we add for our customers. We are able to transform raw material to high tolerance precision machined components. We can machine or weld process chambers and gas lines to the tightest of leak rate specifications. Operational and quality process controls ensure that work is accomplished with the utmost of efficiency.

None of this would be possible without a facility that is capable of meeting the most stringent of cleanliness requirements. With 40,000 sq./ft. of space, 6,000 sq./ft. of which is cleanroom, we have the capacity to take on your design and development or fully mature projects.

Learn more about our Cleanroom Manufacturing

Appying lean manufacturing techniques is an integral part of our culture. Our adaptive planning process is tailored to meet our customers low to medium-volume/high-mix requirements. Work cells are set-up with the flexibility and efficiency that our customers have come to expect to ensure consistency of product quality and on time delivery.

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now