- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

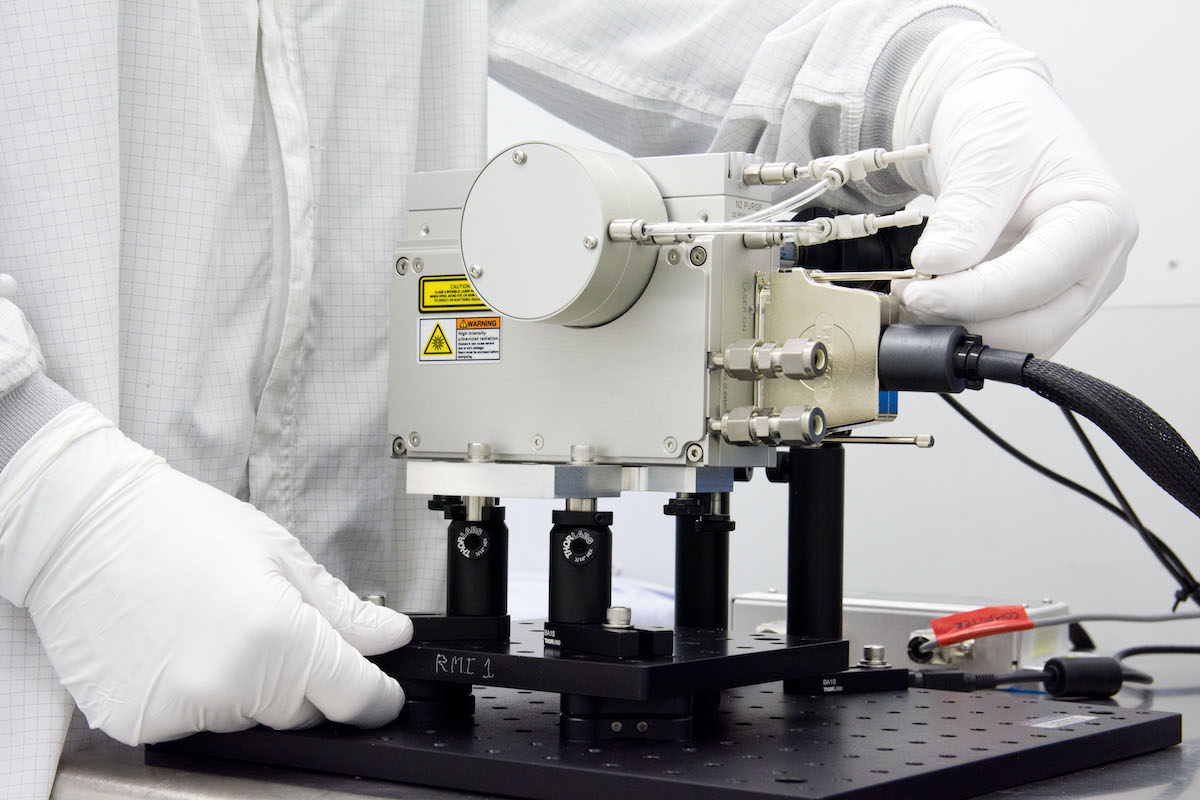

Our Technicians are IPC certified and have many years of experience with electromechanical assembly, test and qualification of equipment and instruments.

The cornerstone of our manufacturing expertise is grounded in the semiconductor industry and over the last 30 years we have broadened our portfolio to include Medical, Optics, Life Science, Nanotechnologies, Gas & HPLC Chromatography and R & D electromechanical equipment, industrial instruments, tools and systems.

We are not limited by product complexity or size. We either utilize your product manufacturing documentation, or we create it internally. We have an engineering team who have managed many successful Design for Manufacturing developments. We can adopt and maintain your manufacturing tooling and fixtures or develop our own in-house. We perform qualification testing to validate integrity and operating performance.

Our versatile approach to electromechanical equipment manufacturing insures optimization of work cells and material flow to processes which are tailored to specific customer requirements and specification. Lean manufacturing processes have been adopted to insure efficiency and repeatability of manufacturing operations and processes.

Our adaptive planning process is tailored to meet our customer’s low to medium-volume/high-mix requirements and exhibit the flexibility required from a manufacturing partner. With a small staff of engineers, we welcome any electromechanical manufacturing challenges that you may have which is a testament to our many success stories.

Application and Industry:

Laboratory Instrumentation for a revolutionary Atomic Level Deposition, (ALD) process that is now being adopted for mainstream nanotechnology semiconductor industry.

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now