- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

We at Innovent Technologies are committed to providing high quality and high value add products.

Our employees believe:

To exceed these Quality requirements, we commit to monitoring and continually improving the performance of our QMS and its process against measurable objectives.

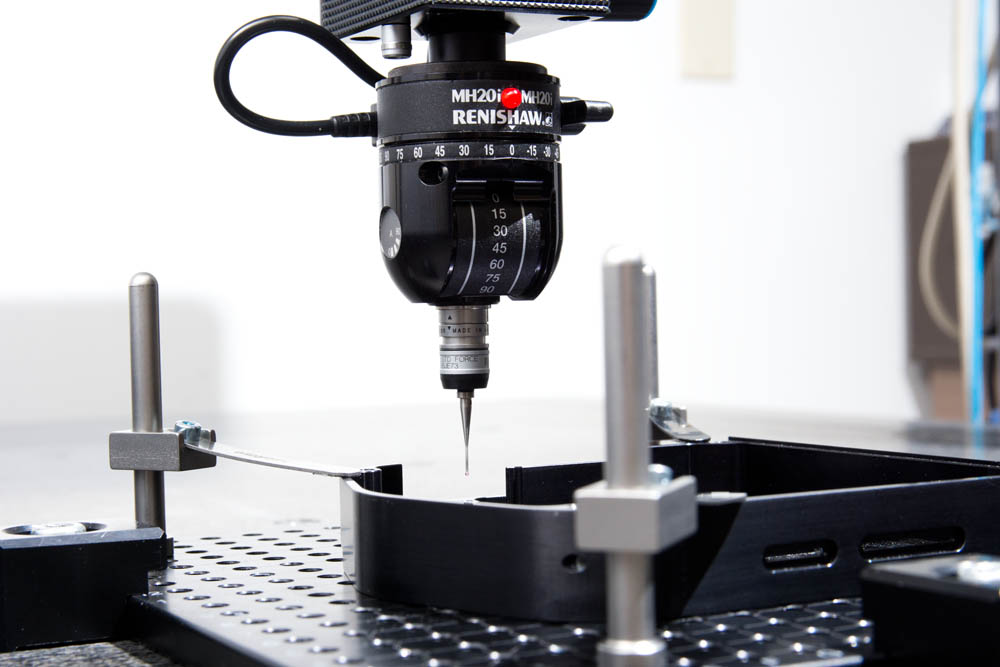

Innovent Testing & Inspection includes:

Our on-staff engineers and technicians are UL508A certified and have also been trained to comply with the IPC620 standard. This means that as a UL508A Panel Shop certified company, we have the in-house expertise to design and build industrial control panels and enclosures that satisfy all the requirements of UL508A. Our certification to the UL process is complemented by the value-add of complying with the strict workmanship standards established in accordance with IPC620 guidelines for all our Box Build work.

This standard defines acceptability criteria for crimped, mechanically secured, and soldered interconnection and the corresponding lacing/restraining criteria associated with cable and harness assemblies; in a word, workmanship. By adhering to these standards, you’ll know that a consistent manufacturing process has been put in place.

For Innovent, the IPC620 standard of workmanship is a perfect complement to our precision machining and clean room assembly work. It shows our wide range of capabilities for manufacturing not just panels, but more complex electromechanical systems inside panels.

UL508A is more than a standard, it is a strictly controlled certification process that ensures compliance to the following criteria:

Once our UL508A MTR (Manufacturing Technical Representative) confirms that the panel or enclosure design is compliant, we can then build the product according to the design specifications. To complete the process, the MTR will host follow-up inspections with certified auditors to verify that the panel manufacturing remains compliant with the standard.

By meeting these requirements, we are then allowed to apply the UL mark to the panels that we have manufactured to the standard. Only a certified contract manufacturer, such as Innovent, has the authority to apply the UL 508A mark to the assembled products built and can only do so if this verification process has been strictly adhered to.

By following this process, your customers will know can be assured that, with the UL mark on it, the panel they purchase from you will be ready for install knowing it meets UL508A .

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now