- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

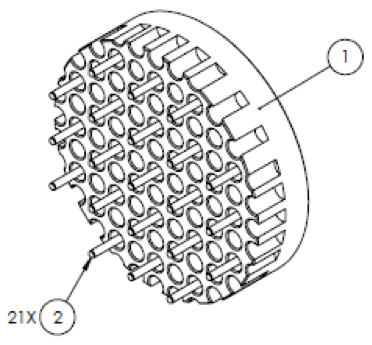

The customer came to us with a challenge to manufacture a complex precision machined gas distribution shower head. A gas distribution shower head is typically utilized to uniformly deliver gas precursors to a processing zone above a substrate typically located in a vacuum chamber to deposit materials such as thin films, onto a substrate. Typical process applications include: Etch and various forms of Chemical Vapor Deposition, (CVD). This unique design required that hundreds of tubes be pressed, (sandwiched) between upper and lower precision machined plates. The challenge was to design fixturing to facilitate the pressing process, insuring that overall dimensions would comply with very tight specifications without damaging the part.

The engineering team accepted the challenge and presented a Design & Development plan to the customer to manufacture the custom precision machined assembly. Key to the project was a Pin Press Fixture design which needed to be a precision machined component in its own right to insure that the pins and plates would go together uniformly without sustaining damage to the components. Several attempts were made and DFM techniques were examined and implemented to insure quality and consistency of the fabrication and manufacturing methods.