- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

We most often work with aluminum and stainless steel but have experience fabricating a wide range of other alloys. Our engineering staff has the capability to develop manufacturing plans to meet the toughest requirement.

If your component designs call for low to medium volume or a variety of similar types of parts that are best suited for the vertical and horizontal milling processes, then we are the right choice.

Do you have only a design idea, proposal or concept that requires electromechanical assembly, parts manufacturing, box builds, precision machining, or clean room assembly? Alternatively, do you have a well-defined design but lack knowledge regarding the fabrication process required to produce your components and systems? In either case, our engineers and production staff will work with you to apply scientific principles, engineering knowledge, and professional experience to determine how wide or tightly controlled features and/or tolerances need to be without adversely affecting price or the outcome of a process. We specialize in design for manufacturing and can discuss many case studies where we have delivered superior results.

Once your components come off our CNC tools, they may require secondary processes such as plating, electro-polishing, painting to finish a part or an electromechanical assembly. We augment our internal resources to accomplish those operations across all project complexities with longstanding relationships with suppliers who specialize in those services. Additionally, your parts would never leave our facility without passing strict quality control guidelines tailored to your precise specifications.

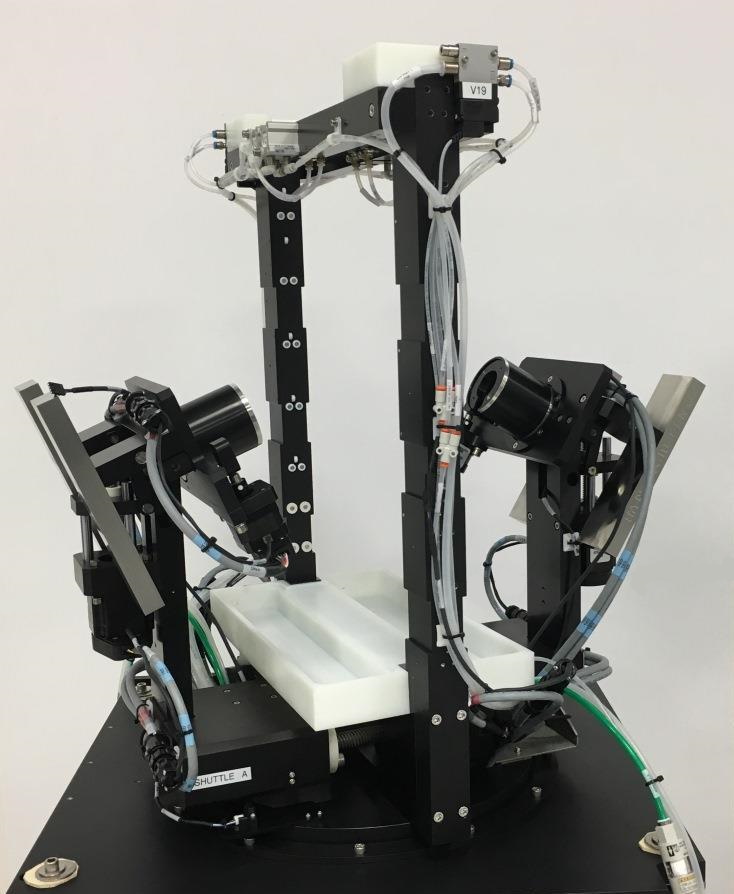

Your one-stop shop for complete fabrication, machining, welding and clean room assembly to exceed your project needs.

Download The Capabilities OverviewYou have challenges, and we certainly understand that. Put our expert engineers to work on YOUR projects and challenges.

Tell Us About Your Project & Make Manufacturing EasyDownload this new guide and know the exact questions to ask as you review your vendors.

Download Now