- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

You need to have your internal resources concentrating on your organization’s core competencies and IP.

So, what capabilities should that box build supplier possess? What are your expectations and most importantly, can your potential manufacturing solution be trusted to deliver products on time with zero defects?

You need to feel confident that the manufacturer’s internal processes will consistently produce high quality products without major changes to how they do business now.

You need to know that when the products are received, they will be plug-and-play ready.

You’ll need to rely on your outsource partner to have highly qualified technicians that are trained, certified and possess the skill set to reliably perform your specific set of manufacturing and test tasks.

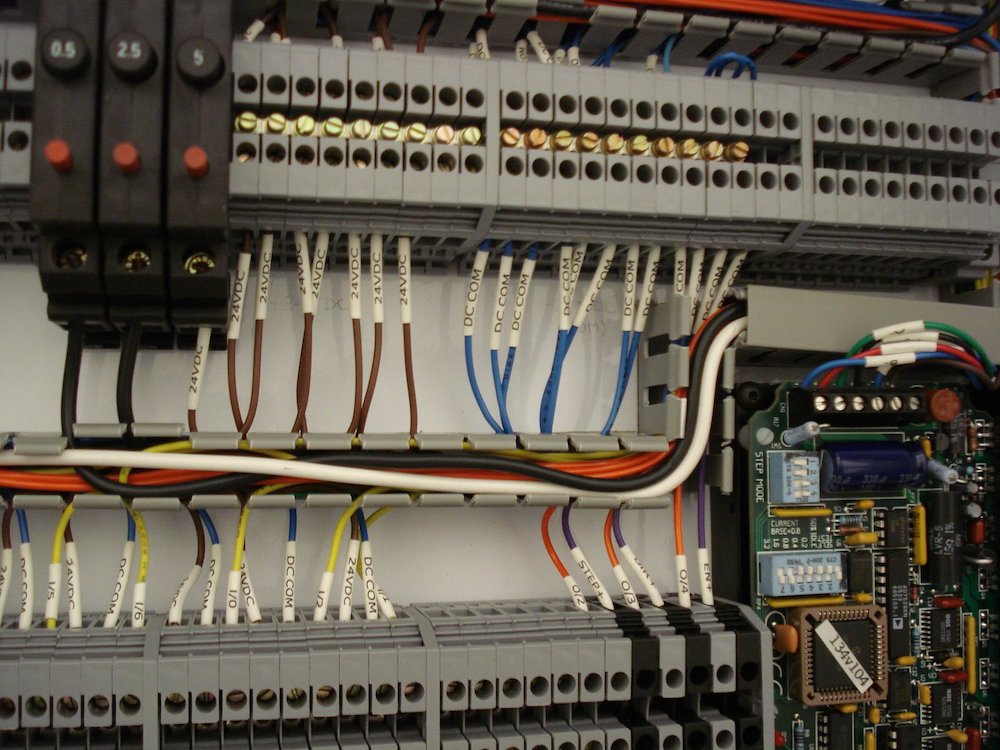

Your partner must have access to suppliers who can deliver the commercial and fabricated components as specified on the BOM. This might include a wide range of parts including sheet metal, fabricated parts, PCB’s, PLC’s and other electrical components. Additionally, the suppliers’ procurement teams need to have commodity specific knowledge so when faced with product obsolescence or design changes, they know where to go to find the right parts or offer alternatives. This is extra vital with today’s supply chain issues.

Your box build supplier must have an engineering team in-house who have the ability to understand the scope of the project and know what internal resources are best suited for the particular product type from prototype to the production phases. You need confidence the suppliers’ engineers can develop supplemental documentation such as manufacturing work instructions, build books, and quality check lists to ensure that the work cell is set-up to be 100% efficient.

It should also be an expectation that the suppliers’ engineers and production staff work together to implement lean manufacturing techniques by periodically revisiting the DfM process to ensure product quality, implement manufacturing efficiencies, and investigate cost reduction ideas.

Box builds are a sub-assembly of a larger system and should be thoroughly tested. Your outsource supplier needs to have the resources to develop a test plan and fixtures that can be used to validate these sub-systems as stand-alone units.

It’s important to work with someone with the qualifications to get the job done right the first time.

There’s no substitute for an in-person meeting with the team and to tour the factory. Due to pandemic or geographics restrictions, this can all be done virtually and has proven to be just as effective. A specific engineer will be assigned to you at the onset of the relationship. This single point of contact, backed by the support of the entire organization, provides an unparalleled level of service. This approach provides you with valuable insight into our capabilities and demonstrates how current projects are being processed.

It’s essential to clearly communicate the specifics of the project so you can make sure your parameters are accurately conveyed and we understand exactly what you need. If you have a complete documentation package, that is of course the preferred way of understanding the project scope. If, however, your documentation is incomplete or you anticipate changes, we’ll work with you to mature that documentation package as we work through the prototype and preproduction phases.

We understand that your products have additional requirements that very few contract manufacturers are in the unique position to offer. For example, a subset of your box build products may require component fabrication operations such as machining and welding. Having the ability to do these operations in house reduces part touch and transport time which inevitably reduces the potential for damage and longer lead-times to you. If cleanliness is a concern, we have years of experience in the semiconductor, medical and life science industries which call for strict adherence to cleanliness protocol during the final phases of their manufacturing and assembly processes.

When you work with us you can be continually and actively involved in the manufacturing process through the different phases of production. Our goals in the Concept and Design phases are to work with you to develop the concept and to achieve design and cost specification within the time allotted no matter how many times changes are made. We have participated in co-builds at our customers’ sites or have had our customers’ employees work here to teach assembly and test processes. This reduces the manufacturing learning curve drastically.

Our unique approach to custom box build combined with our precision machining, cleanroom assembly facilities, and engineering team make us a cost-effective solution for a wide range of complex assemblies. We can deliver large or small production rates with the same attention to detail in quality and on-time delivery.