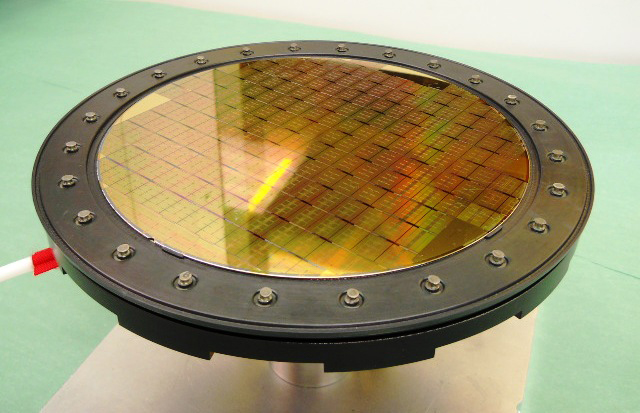

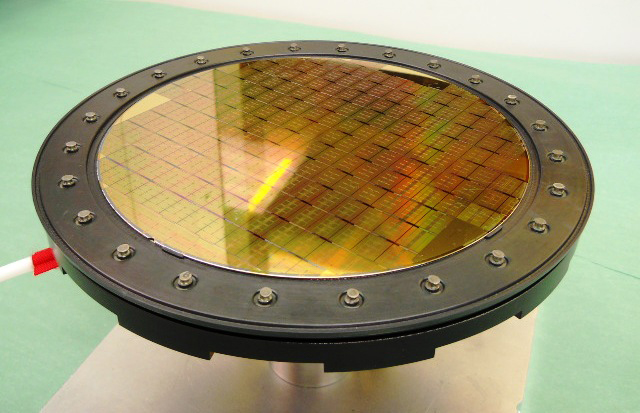

It’s no secret that 2022 will be a banner year for semiconductor manufacturing both for the chip manufacturers themselves, but also the supporting industries who make ALD, substrate handling robotics, and all the supporting electromechanical subsystems that go into chip production.

A key question at every level of semiconductor manufacturing subsector is how to maximize output while utilizing your physical and intellectual resources in these boom times. More simply, to maximize your profitability, what do you manufacture in-house and what do you send out to semiconductor equipment contract manufacturers who can fill in the gaps at every level of the production process.

For example, at Innovent, we have focused our efforts on leveraging our key advantages as a contract manufacturer. The result is working with a multiple month backlog for predictability and the ability to add in a quick reaction project when we can add major value for a customer. These advantages include:

For example, at Innovent, we have focused our efforts on leveraging our key advantages as a contract manufacturer. The result is working with a multiple month backlog for predictability and the ability to add in a quick reaction project when we can add major value for a customer. These advantages include:

For example, at Innovent, we have focused our efforts on leveraging our key advantages as a contract manufacturer. The result is working with a multiple month backlog for predictability and the ability to add in a quick reaction project when we can add major value for a customer. These advantages include:

For example, at Innovent, we have focused our efforts on leveraging our key advantages as a contract manufacturer. The result is working with a multiple month backlog for predictability and the ability to add in a quick reaction project when we can add major value for a customer. These advantages include:

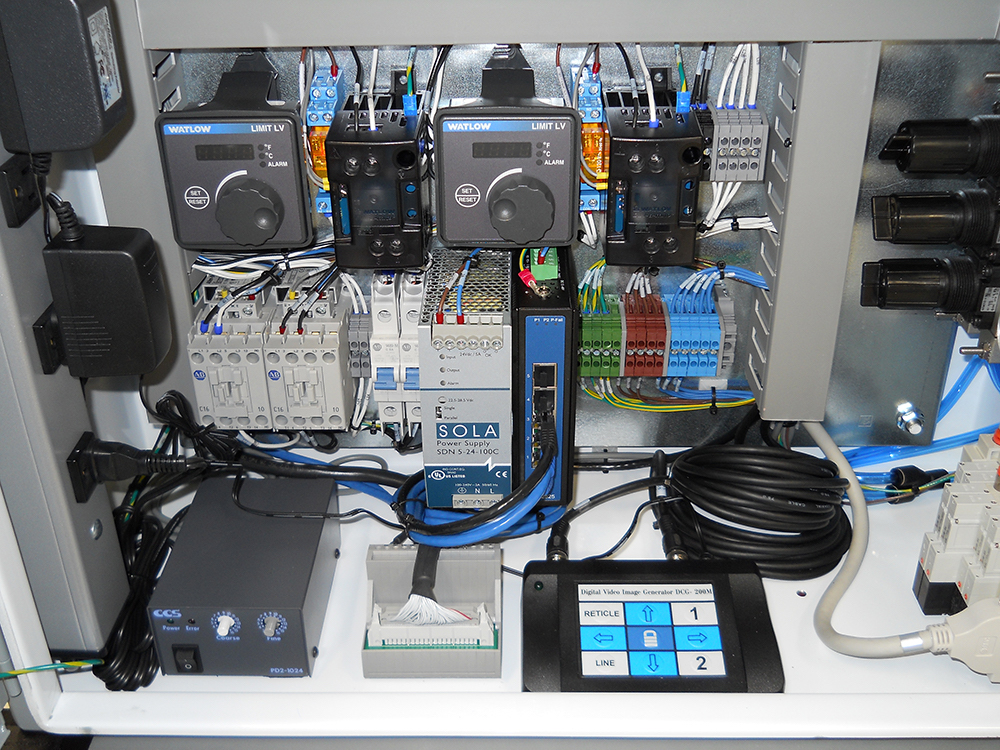

- Superior supply chain insights and established relationships to find those key components like valves, fittings, mass flowmeters, controllers, and a wide range of semiconductor manufacturing equipment component parts

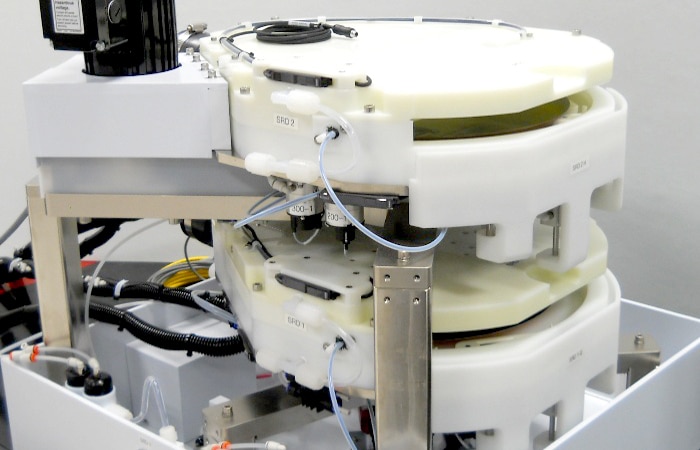

- Legacy of producing the finest, affordable precision machined parts for complex electro-mechanical systems

- Clean room manufacturing and assembly with experience in semiconductor, optical equipment, life sciences and robotics manufacturing subsystems

All this has been very timely for the current major surge in semiconductor manufacturing to meet the needs of the new IOT economy and post-COVID 19 demands. The industry is exploding with the need to manufacture more equipment to support all the orders and get the backlog back to a manageable number. Some details include:All these are presently “proposals”, but they do indicate clear intent to provide federal funding to improve the USA semiconductor production capability and accelerate our recovery from the current backlog of delivery across a wide range of goods awaiting chips. It’s exciting to be sharing in this semiconductor manufacturing period of rapid expansion. It was predicted years ago when IOT became a real possibility, artificial intelligence became mainstream in the automotive industry, and industry became aware that manufacturing in China was not going to be the long-term solution that it had promised. Now Innovent is ready with the expertise and expanded physical capabilities to be a strong contract manufacturer for the semiconductor industry. We are proud to be a strong part of the USA manufacturing sector and filling the role as a premier electro-mechanical contract manufacturer in industries like semiconductors, life sciences, medical device manufacturing equipment, and robotics.

- Senate authorization of $190B for new semiconductor technology and $54M for new chips in its version of the China technology threat bill

- The House is considering similar provisions

- Tax credits for semiconductor manufacturing in the USA are under consideration

- Funding for a U.S. Innovation & Competition Act, which would boost investment in high-tech fields including semiconductors