- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

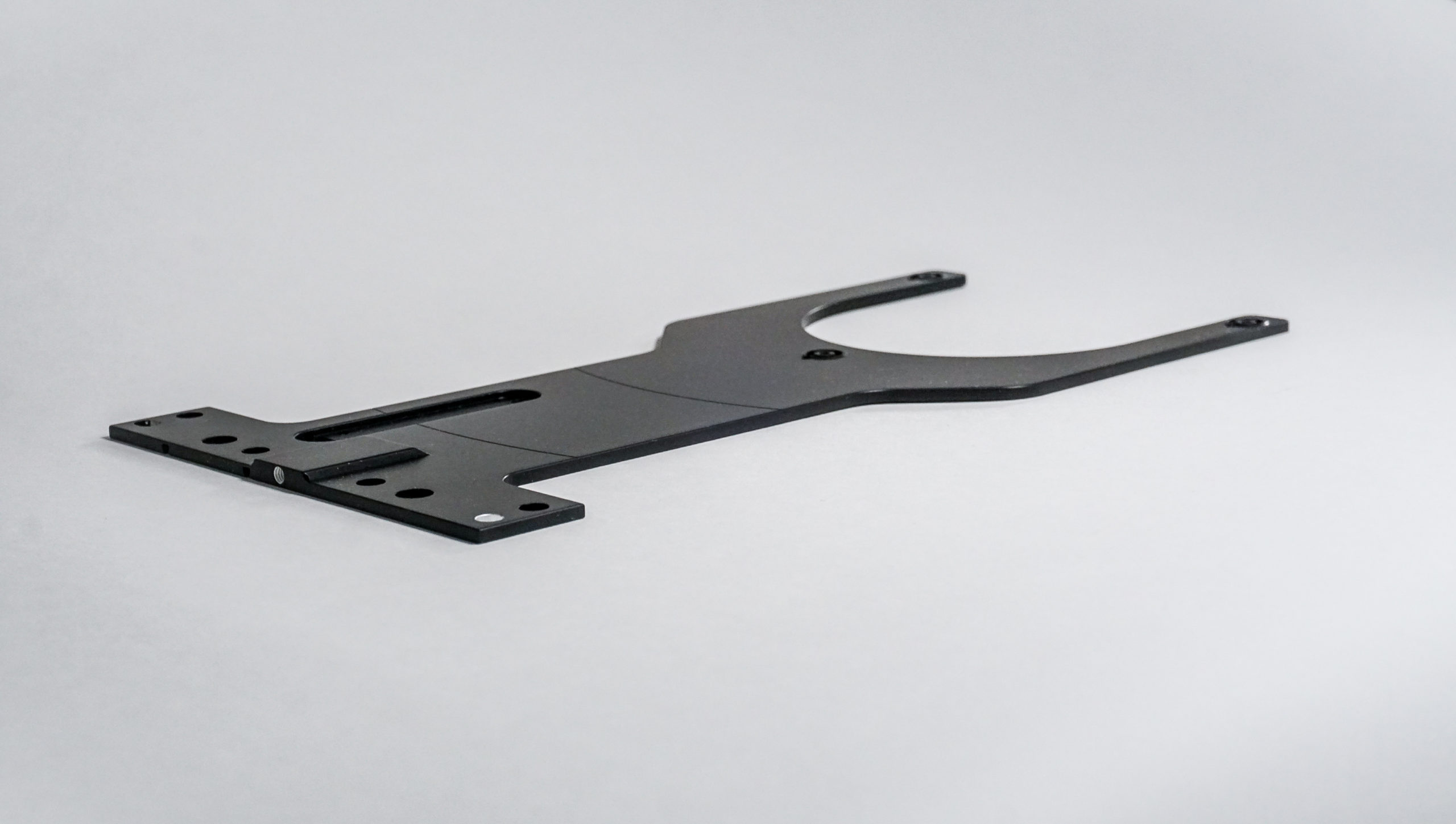

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

Glass, on the other hand, is a brittle and transparent material that is used in various applications, such as in LCD and OLED displays, solar panels, and optical components.

1. Contact force: The contact force between the end effector and the substrate needs to be carefully controlled to avoid damaging the material. Glass substrates, in particular, are very sensitive to pressure and can break easily. Therefore, the end effector needs to apply a gentle and uniform force to avoid cracking the substrate.

2. Gripping mechanism: The end effector needs to have a gripping mechanism that can securely hold the substrate without damaging it. For silicon substrates, vacuum-based end effectors are commonly used, which use suction to hold the substrate. For glass substrates, suction-based end effectors can also be used, but other methods such as electrostatic or mechanical clamping may be preferred.

3. Surface properties: The surface properties of the end effector need to be compatible with the substrate material to avoid contamination or damage. For example, the end effector may need to have a non-reactive surface coating or be made of a material that is chemically compatible with the substrate.

4. Cleanroom compatibility: Both silicon and glass substrates are commonly handled in cleanroom environments, which require the end effector to be designed for use in such environments. The end effector needs to be clean and free of particles or contaminants to avoid introducing contamination into the manufacturing process.

5. Customization: The end effector may need to be customized to match the size and shape of the substrate being handled. For example, some glass substrates may have curved surfaces or non-standard sizes, which require a custom-designed end effector to handle them safely and effectively.

Overall, the end effectors used to handle silicon and glass substrates need to be carefully designed and selected to ensure safe and efficient handling without damaging the delicate and sensitive materials.