- Solutions

- Capabilities

-

-

Design

-

Fabricate

-

Assemble & Test

-

QA

-

-

- Fabricated Parts

- Industries

- About

Get Engineering Help:(978) 538-0808

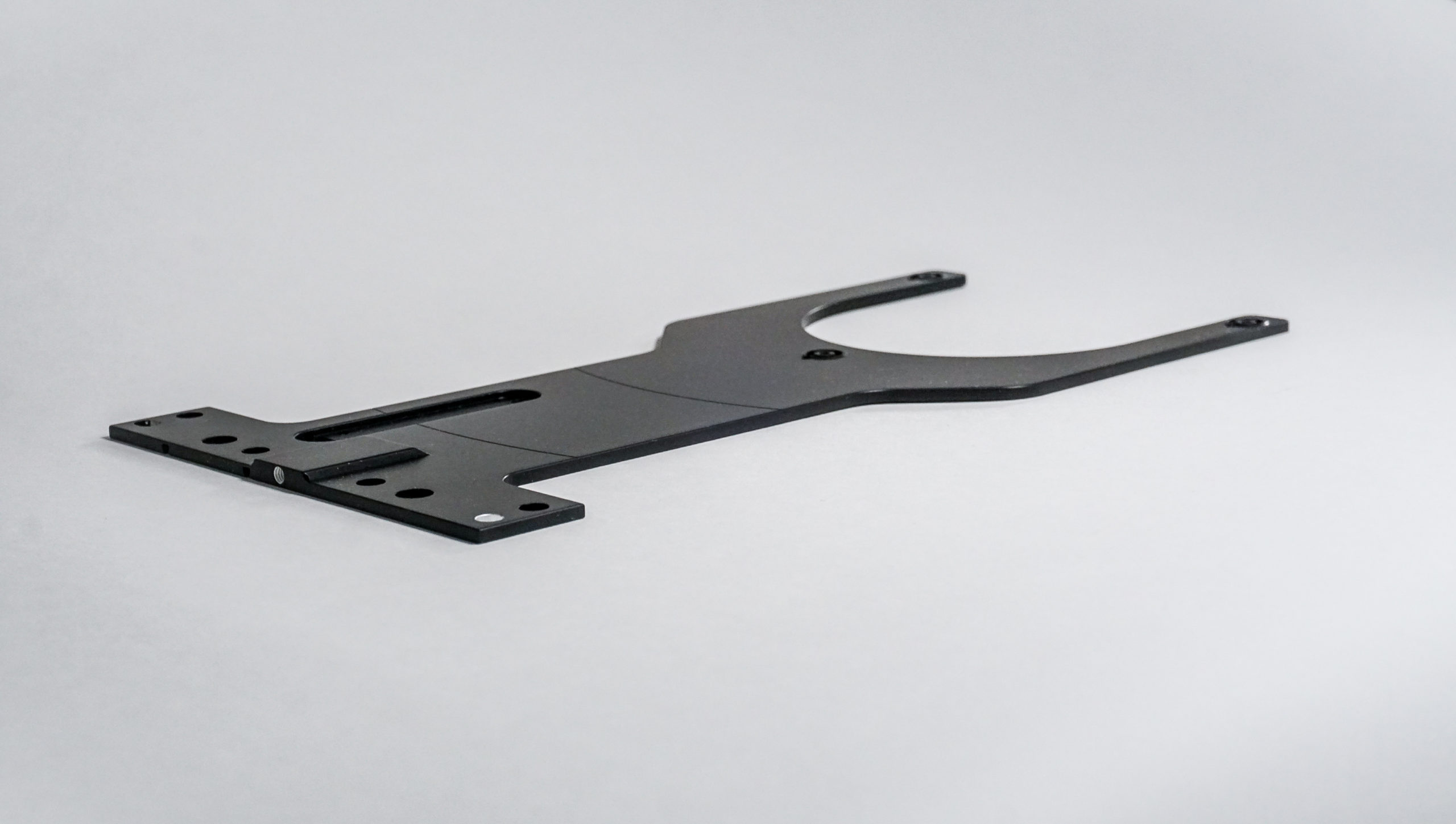

End effectors, also known as end-of-arm tools, are devices or tools that are attached to the end of a robotic arm or manipulator. These tools are used to enable the robot to interact with and manipulate its environment, allowing it to perform a wide range of tasks that would be difficult or impossible for humans to do manually. End effectors come in various forms, from simple grippers to complex tools that can perform specific tasks like cutting or welding materials, performing inspections, or handling delicate objects.

One of the most common types of end effectors is the gripper. Grippers are used to grasp and hold objects, and can come in a range of shapes and sizes depending on the requirements of the application. Some grippers are designed to grip flat objects, while others are designed to grip round or irregularly shaped objects. There are also specialized grippers, such as magnetic grippers that can be used to pick up and move metallic objects, and vacuum grippers that use suction to hold objects in place.

Another type of end effector is the welding tool. Welding tools are used to fuse two or more pieces of metal together, and can come in various forms, such as arc welders, spot welders, or laser welders. These tools are often used in manufacturing applications to join metal parts together, and can be customized to suit specific applications.

For example, a camera or sensor can be attached to the end of a robotic arm to inspect parts or products for defects. This allows manufacturers to automate quality control processes and improve efficiency.

In addition to these examples, there are many other types of end effectors that can be used for a range of applications. For example, in the food industry, robots can be used to handle and package food products using specialized end effectors like grippers or suction cups. In the medical industry, robots can be used to perform surgeries using specialized tools that can make precise incisions or sutures.

The choice of end effector depends on the requirements of the task, the properties of the objects being manipulated, and the type of robot being used. In many cases, end effectors can be customized to suit specific applications, allowing robots to perform tasks that would be difficult or impossible for humans to do manually.

There are many advantages to using robots with end effectors in manufacturing and other applications. Robots can work continuously and consistently, without the need for breaks or rest, which can improve efficiency and productivity. They can also work in hazardous or dangerous environments, reducing the risk of injury or accidents for human workers. Additionally, robots can be programmed to perform tasks with a high degree of precision, accuracy, and repeatability, which can improve product quality and reduce waste.

In summary, end effectors are devices or tools that are attached to the end of a robotic arm or manipulator, allowing robots to interact with and manipulate their environment. They come in various forms and can be customized to suit specific applications, making them ideal for a range of manufacturing and other industrial applications. The use of end effectors can improve efficiency, productivity, and safety, while also enabling robots to perform tasks that would be difficult or impossible for humans to do manually.